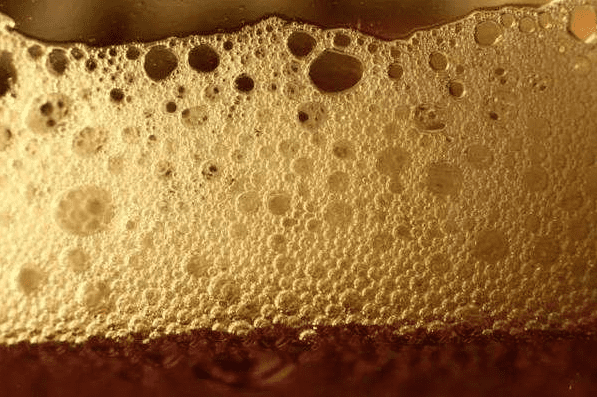

During the fermentation process, the generation of foam may have a series of effects, such as foam will directly affect the fermentation efficiency, because in the fermenter, the presence of foam may lead to a reduction in the working load to prevent overflow, which affects the loading factor of the fermenter. Usually, the loading factor of the fermenter is about 0.7 to leave enough space to deal with the generation of foam. In addition, fermentation involves many microorganisms and strains. Stable foam will hinder gas exchange, resulting in the ineffective discharge of carbon dioxide in the bubbles, while limiting the entry of oxygen, thereby affecting the normal respiration of microorganisms. For some specific fermentation products such as proteases, foam may cause these products to be inactivated, thereby affecting the quality of the final product.

What are the factors involved in the generation of foam during fermentation? During the fermentation process, ventilation and stirring are necessary steps to ensure the growth and metabolism of microorganisms. But this will also cause air to mix into the culture medium and form bubbles. The greater the ventilation volume and the faster the stirring speed, the more foam will be produced. The physical and chemical properties of the fermentation broth, such as pH value, temperature, and ionic strength, have a great influence on the formation and stability of foam. For example, some microorganisms produce surfactants during metabolism, which reduce surface tension and increase foam stability.

Fermentation defoamers do not affect the taste of products, defoam quickly, and suppress foam for a long time. They are used in food industries such as soy products, dried tofu, bean curd sticks, dairy products, beverages, sugar industry, soy protein extraction, sauce and vinegar brewing, and cigarette holder adhesives. Food defoamers are fast, suppress foam for a long time, do not react with substances in the foaming system, and do not affect product quality.